The principle

Wie funktioniert unsere Technologie ARA-LT®?

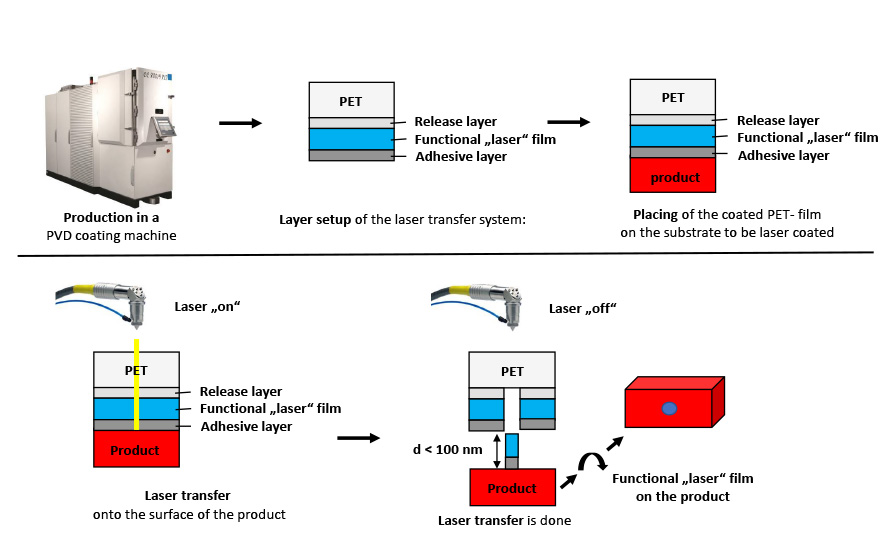

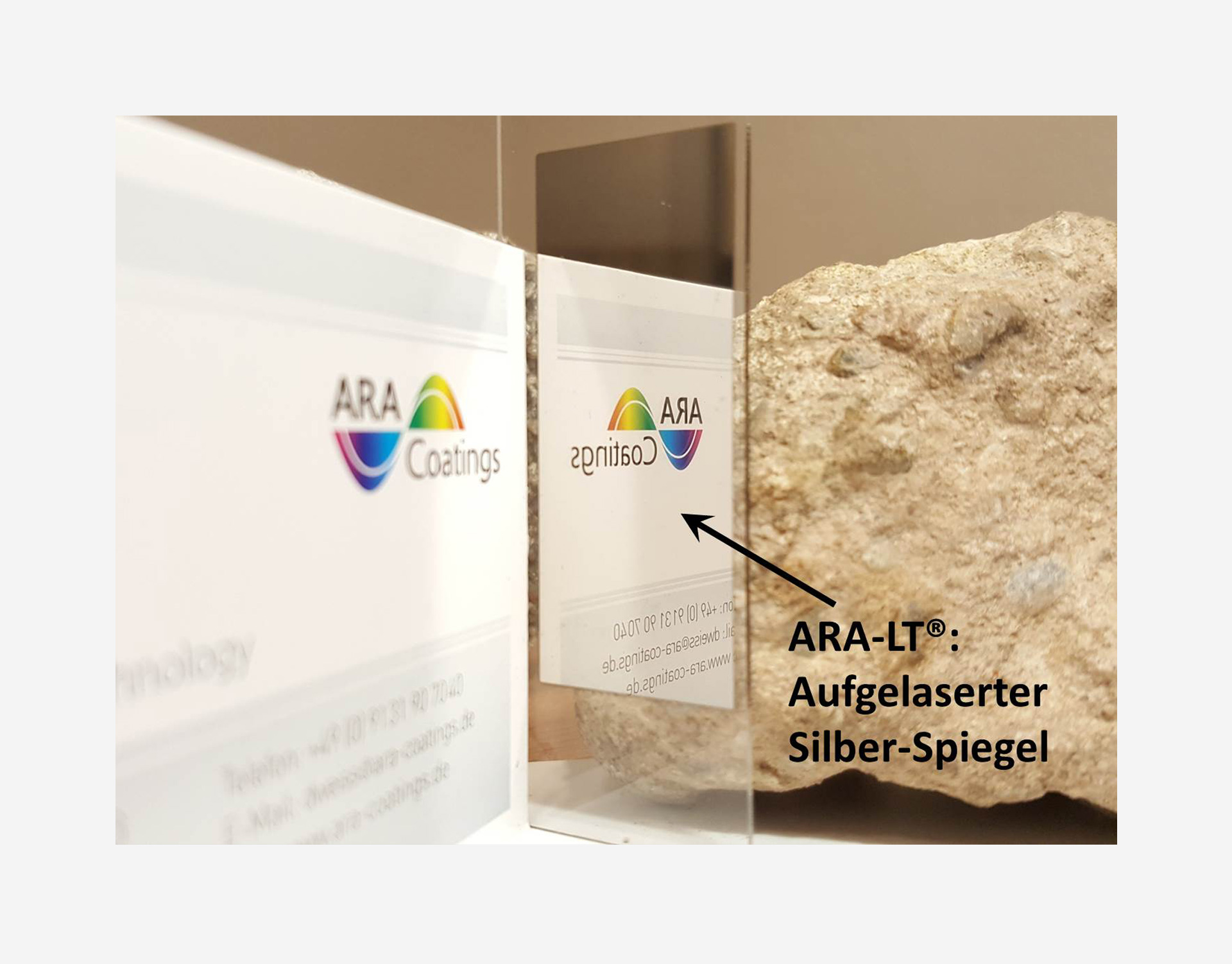

ARA-LT® - is based on the process “LIFT” (= laser-induced forward transfer) that has been known for more than 50 years.

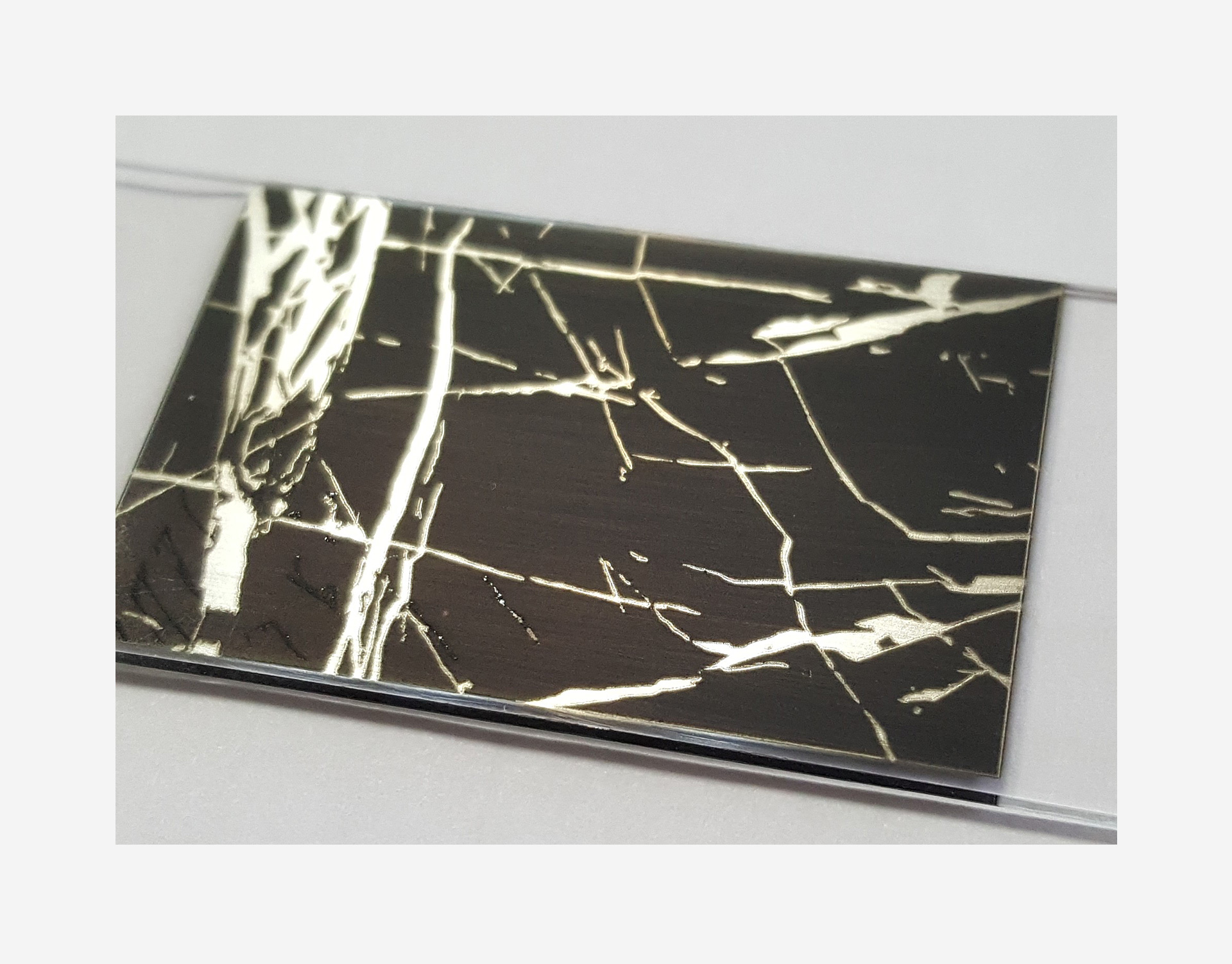

We have now further developed this process in such a way that, using specific PVD layers on a carrier material (= “ARA-LT® laser foils”), almost all metals, semiconductors, and insulators, as well as other inorganic materials, can be “lasered” in the highest quality. Also, specific functionalities can be incorporated into the “laser coatings” and thus into the product surfaces.

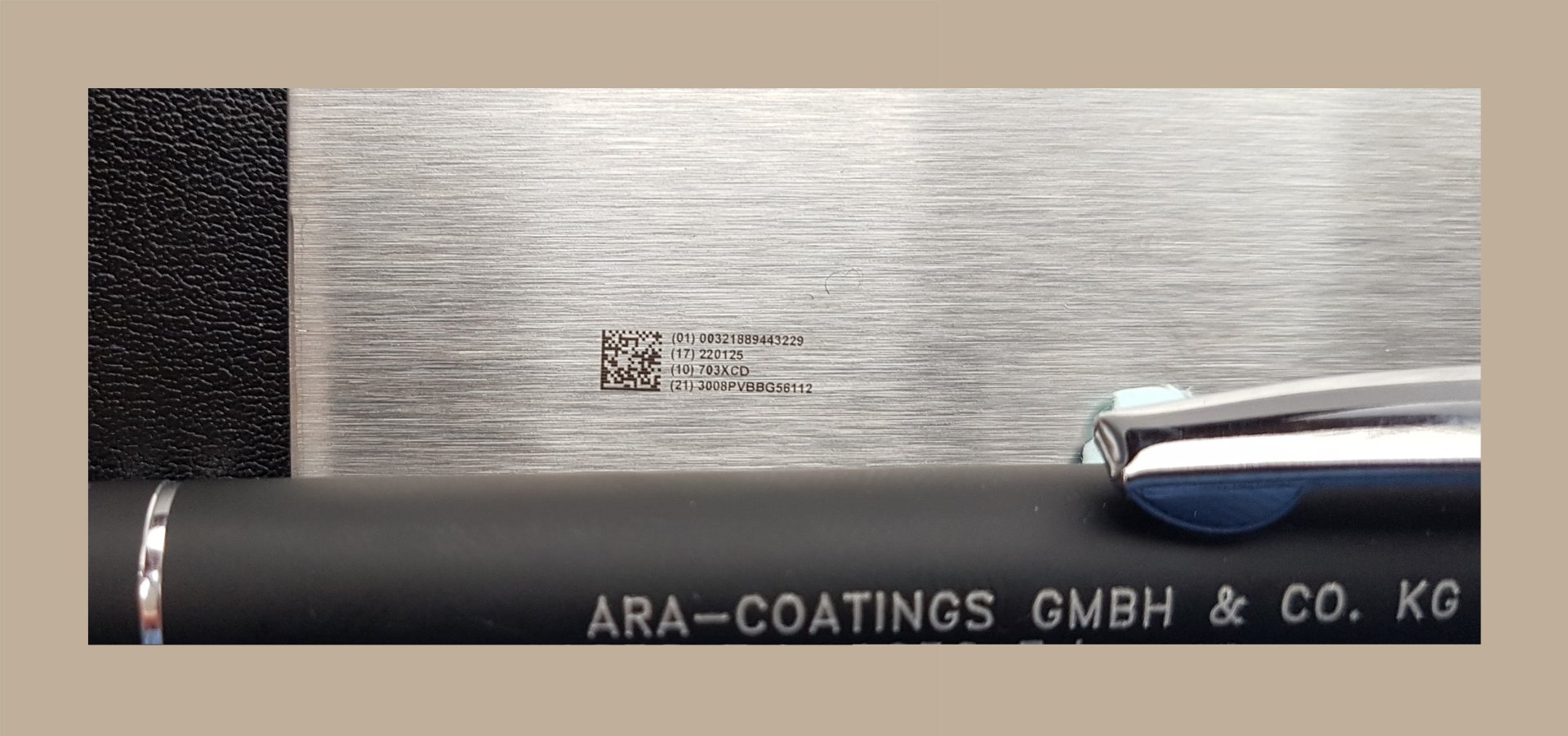

Furthermore, laser marking and coating with ARA-LT® laser foils works very quickly and because the latter is also available in large quantities, this technology is an interesting alternative not only in terms of quality but also in terms of price for numerous applications. Here you can see a video demonstration of a manually performed laser-induced PVD marking.

ARA-LT® laser foils can also be integrated into large-scale production lines.

Place the ARA-LT® laser film on the product surface> activate the laser> remove the film

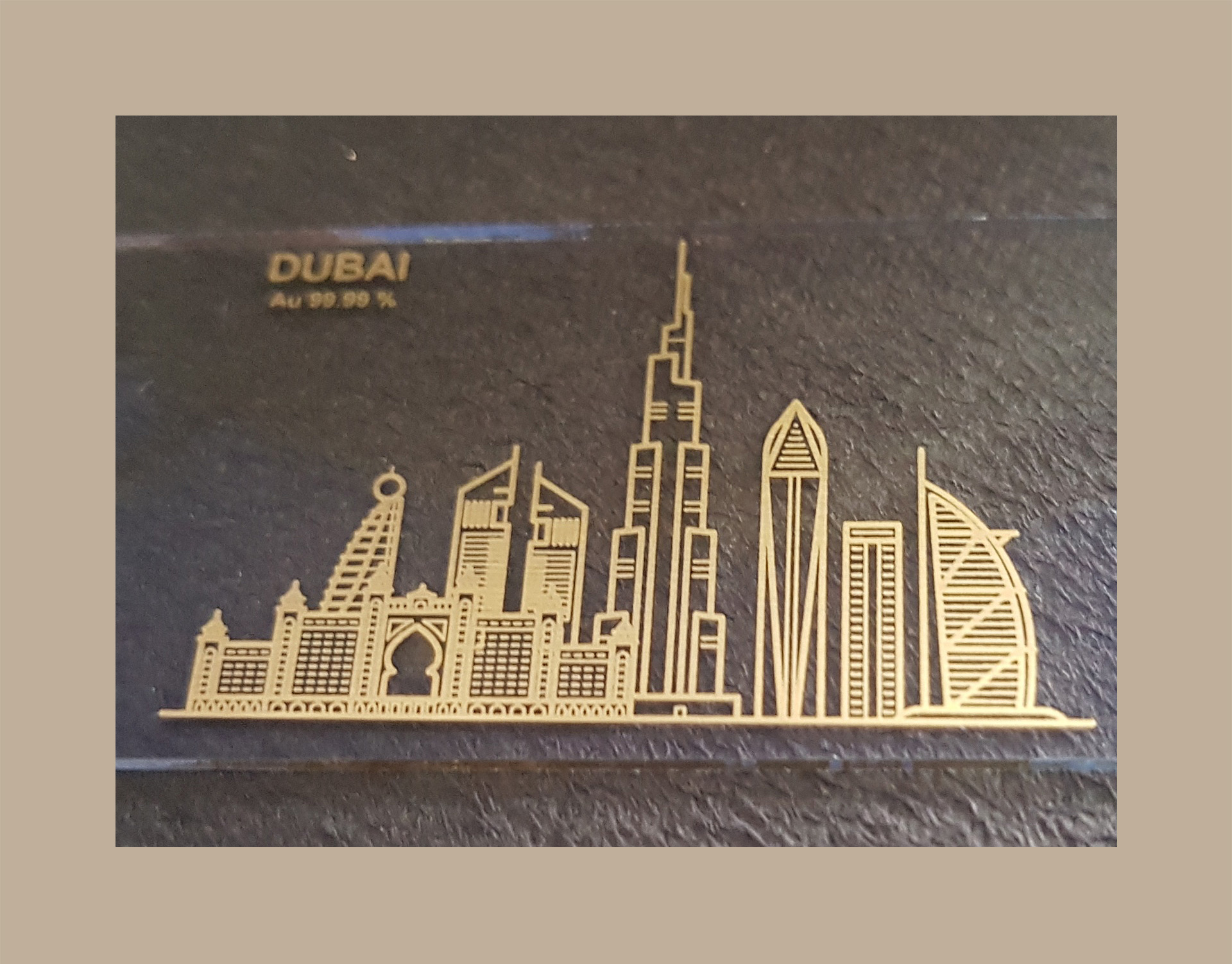

Labeling solutions: Examples

Functional laser PVD coatings ARA-LT®: Examples

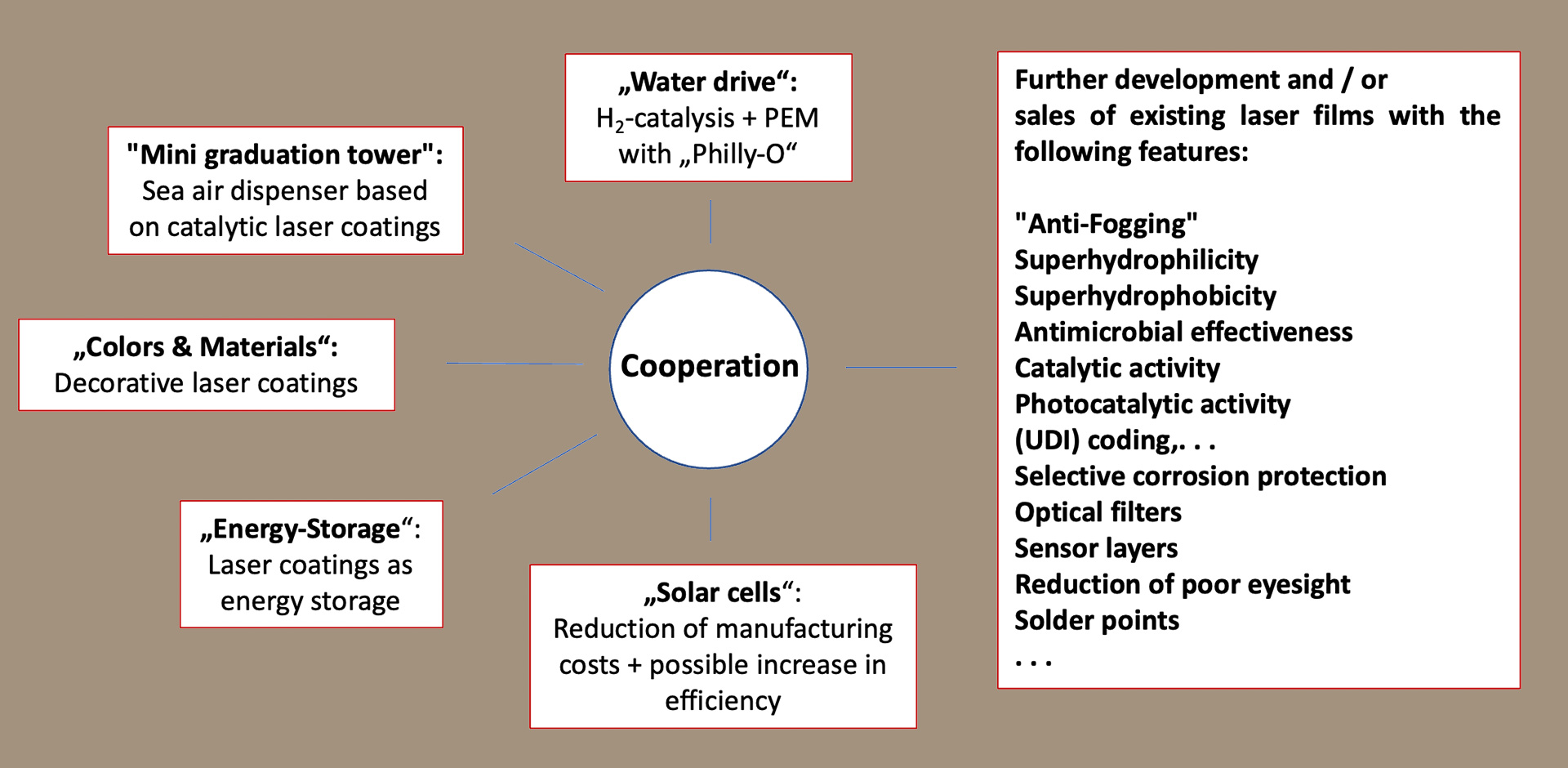

Laser-Induced PVD Coatings ARA-LT®: Opportunities for Cooperation