The laser-induced chemical change

An important property of laser-transferable PVD coatings is that they have a very porous structure. This also provides an enormously large internal surface area, which causes a “nano-effect” - namely, a reduction in the melting temperature of the PVD coating material in question.

An important property of laser-transferable PVD coatings is that they have a very porous structure. This also provides an enormously large internal surface area, which causes a "nano-effect" - namely, a reduction in the melting temperature of the PVD coating material in question.

On the one hand, this opens up the possibility that metals and other inorganic substances can be transferred with such low laser power that the product surface is not affected (see last week's article). In addition, chemical changes can also be induced: By selectively increasing the laser power, PVD layer transfer can be used to partially or even completely oxidize metals.

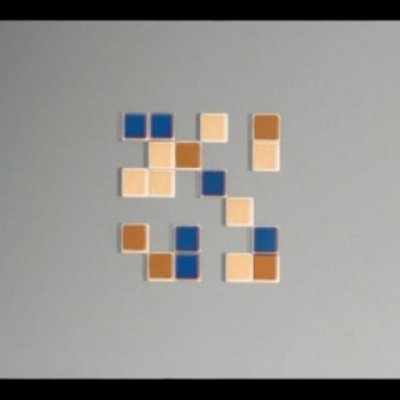

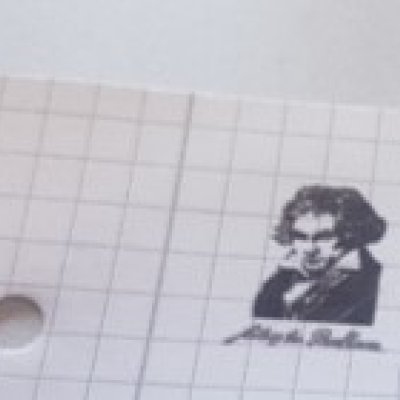

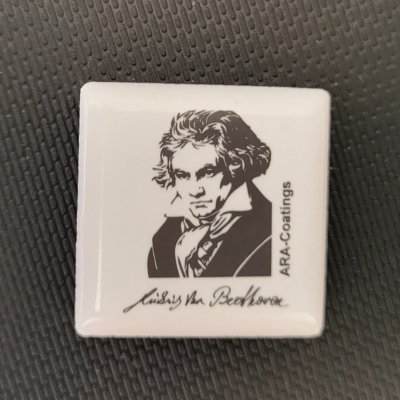

For example, starting from metallic titanium, sub-stoichiometric but extremely durable black TiOx can be generated (Fig.1) , even on paper (Fig.2). It is also possible to generate many colors by using interference effects (Fig. 3) - or white areas and "non-viewing-angle-dependent" colors (Fig. 4,5)